Welcome to the WorkShop

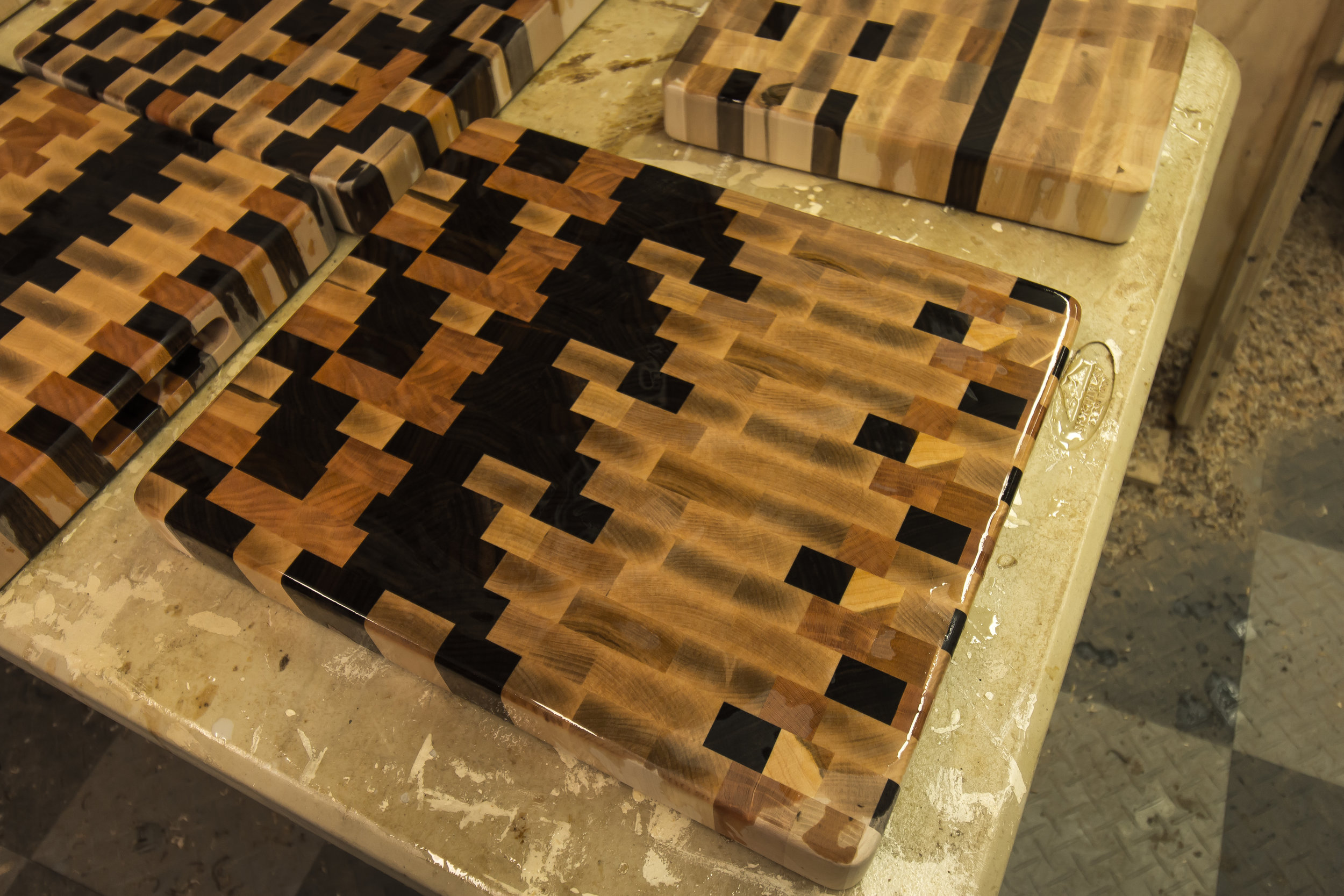

During peak season, a lot of rough lumber goes through a huge transformation in my shop. Many pieces start at the planer which shaves off a thin layer of wood from the top and bottom of the face of the wood. This cleans up the surface and begins the process of refining the wood so it can then progress onto other stages bringing it closer to the final product. Most of my lumber is sourced locally and also comes from removed property trees. I use mostly maple, walnut, and cherry but do also use other species such as oak and ash. Every once in a while, I will source exotic species such as purple heart, zebra wood, bloodwood aswell as many others which have beautiful colors.

I make a large variety of products and this requires me to have a large amount of machinery in my work space. Many pieces enter the table saw where it is cut to dimensions needed for cutting boards or to be cut down further into segments for wooden bowls. These pieces are then glued into their respective orientations or shapes and need almost a full day for drying to then proceed to the next steps. This includes further cutting for projects like cutting boards or wood turning to essentially take wood and make it round in projects such as pepper mills, bottle stoppers, and bowls.

Table Saw

The most frequently used machine in my workshop is the 3 horse power Saw Stop table saw. It is the fastest way to break down lumber into thinner pieces suitable for my project needs. Just about every single piece of wood goes through this machine at least once during its time in the shop.

Bandsaw

The bandsaw is a more unique tool that is not essential for most woodworking but offers some advantages that can't be done by other machines. This is a process called "resawing" where a vertical piece of wood is split in half to create two thinner pieces of wood. Many of my projects undergo this process to drastically cut down on time and easy replication of some glued up designs.